Unveiling the Process Flow of Qingdao Hongcheng Hong Epoxy Powder Coating Equipment

Release time:

2025-09-19

Unveiling the Process Flow of Qingdao Hongcheng Hong Epoxy Powder Coating Equipment

As a leading enterprise in China's anti-corrosion and thermal insulation sector, Qingdao Hongchenghong Anti-Corrosion & Thermal Insulation Co., Ltd. has set an industry benchmark in fields such as pipeline engineering and steel structure corrosion protection, thanks to its independently developed epoxy powder spraying equipment. The company's process integrates core technologies like electrostatic adsorption and high-temperature leveling & curing, enabling a fully standardized operational system that spans from pre-treatment of workpieces to final product inspection. This article will delve into the key components of their equipment and processes, shedding light on the technical principles behind the highly effective anti-corrosion coatings.

I. Workpiece Pre-treatment: The Source of Coating Adhesion

The durability of epoxy powder coatings begins with rigorous surface preparation. Qingdao Hongchenghong employs a dual-track pretreatment process combining "chemical + physical" methods:

1. The chemical cleaning line is equipped with a fully automatic spray system that uses an alkaline degreasing agent to remove oil stains, an acid pickling solution to eliminate oxide scale, and a phosphating process to form a dense conversion coating, boosting the coating adhesion to 3–5 MPa.

2. The physical rust removal process incorporates a rail-mounted shot blasting machine, where steel shots impact the workpiece surface at a velocity of 80 m/s, effectively removing SA2.5-grade rust while simultaneously creating a roughened surface with anchor patterns measuring 40–60 μm in depth, thereby enhancing powder adhesion.

3. After pre-treatment, the workpiece must be tested in a salt spray chamber to ensure no red rust appears within 240 hours under neutral salt spray conditions, laying the foundation for subsequent coating processes.

II. Electrostatic Adsorption Spraying: Precise Powder Deposition

Qingdao Hongcheng Hong's core equipment—the epoxy powder electrostatic spraying machine—achieves efficient powder adhesion through three key technologies:

1. The powder supply system features a two-stage fluidized bed design, with the main bed operating at an air pressure of 0.8–1.2 bar and the auxiliary bed at 0.3–0.5 bar, ensuring a powder delivery accuracy error of ≤2%. The powder supply pump’s speed is adjustable between 500 and 1,500 rpm, accommodating spray coating requirements for various pipe diameters.

2. The spray gun system integrates a high-voltage electrostatic generator, delivering an output voltage of 60–90 kV, which charges the powder particles up to 10 μC/g. The spray gun maintains a constant distance of 250–300 mm from the workpiece, with atomization air pressure set at 0.4–0.6 bar, creating a conical spray pattern that achieves a coverage width of up to 400 mm.

3. The recycling system employs a large cyclone separator combined with a pulse-filter cartridge for secondary recovery, achieving a powder recovery rate of ≥98%. The tangential air velocity in the separator is maintained at 18–22 m/s, ensuring efficient collection of coarse particles, while fine powders are filtered through the cartridge and then reused. This process enables a single-spray powder utilization rate of over 85%.

3. High-Temperature Flowing and Curing: Chemical Transformation of the Coating

The curing stage is crucial for shaping the coating's performance:

1. The medium-frequency induction heating system utilizes IGBT modules with an adjustable frequency range of 1–20 kHz, enabling rapid, localized heating of steel pipes. Once the pipe temperature reaches 180–195°C, the epoxy powder begins to melt. At this point, the spray gun is activated for external wall coating, with a powder application rate of 300–600 g/min. The coating thickness is precisely controlled between 70 and 1,200 μm.

2. The curing tunnel employs a combined infrared and hot-air circulation heating system, with the temperature gradient maintained within ±5°C. The epoxy powder undergoes three stages—melting, leveling, and crosslinking/curing—at 200°C.

- Melting stage: Powder particles soften, forming a continuous film layer.

- Flow and leveling stage: Surface tension drives the coating to flatten, eliminating orange-peel defects.

- Curing stage: The epoxy resin undergoes a cross-linking reaction with the curing agent, forming a three-dimensional network structure.

3. The water-cooling system uses a frequency-conversion pump to precisely control the spray flow, reducing the tube temperature from 200°C to 40–45°C within 30 seconds, thereby preventing coating cracks caused by thermal stress.

IV. Quality Control: Ensuring Millimeter-Level Precision

Qingdao Hongcheng Hongjian establishes a four-level testing system:

1. Online Detection: The laser thickness gauge continuously monitors coating thickness, with data fed back to the PLC system for automatic adjustment of spraying parameters.

2. Sampling Inspection: Samples are taken from every 200-meter section of the pipe for adhesion grid testing, bending tests, and impact tests.

3. Laboratory Testing: Salt Spray Test, Cathodic Disbondment Test, and Chemical Corrosion Resistance Test to verify coating performance.

4. Finished Product Inspection: Use an X-ray fluorescence spectrometer to analyze the elemental composition of the coating, ensuring that the epoxy resin content is ≥65%.

V. Technological Breakthrough: Innovative Practices in Double-Coating Application

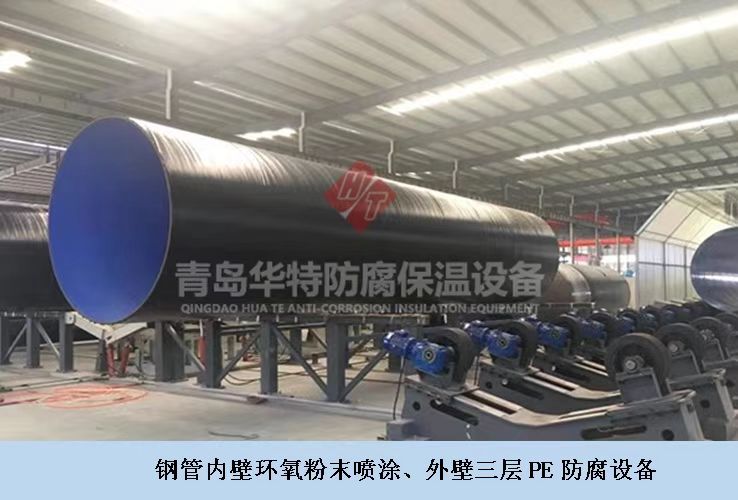

For extreme environments such as deep-sea pipelines, Qingdao Hongchenghong has developed a dual-layer epoxy powder coating process—both internal and external.

1. The inner wall is coated using a mobile spraying vehicle, with the spray gun precisely positioned via a rail system, ensuring a coating thickness uniformity of ±5%.

2. The exterior wall coating is applied in two stages: the front chamber is sprayed with a base-layer epoxy powder, while the rear chamber receives a top-layer modified epoxy powder, creating a gradient functional coating.

3. The double-layer coating achieves a total thickness of 1.2–2.4 mm, increasing the pressure resistance by 30% while reducing the cathodic disbondment radius to within 2 mm.

6. Industry Applications: Bridging the Gap from Land to Deep Sea

This process has been successfully applied to:

1. The West-to-East Gas Pipeline Project – Third Line: Each pipeline section features a coating length exceeding 5,000 kilometers, with the coating expected to last up to 30 years.

2. Bohai Oilfield Subsea Pipeline: Withstands water pressure of -1.5 MPa, and its coating exhibits an impact resistance of up to 8 J.

3. Sichuan Gas to East China Project: The coating remained crack-free after undergoing a low-temperature bending test at -40°C.

4. Urban heating pipeline network: After a 150°C high-temperature cyclic test, the coating adhesion retention rate remained at 92%.

Qingdao Hongcheng Hong's epoxy powder coating equipment technology builds a comprehensive anti-corrosion system through precise pre-treatment, intelligent spray control, and accurate curing processes.

Qingdao Huatex Address: No. 36 Shandong Road, Beiguan Industrial Park, Jiaozhou City, Qingdao, Shandong Province

Sales phone: 0532-87286912

Fax: 0532-87286913

Mobile: 13708952663

Postal Code: 266300

Website: http://www.htffbw.com

E-mail: 1871245076@qq.com

Related news

2025-09-17

Share